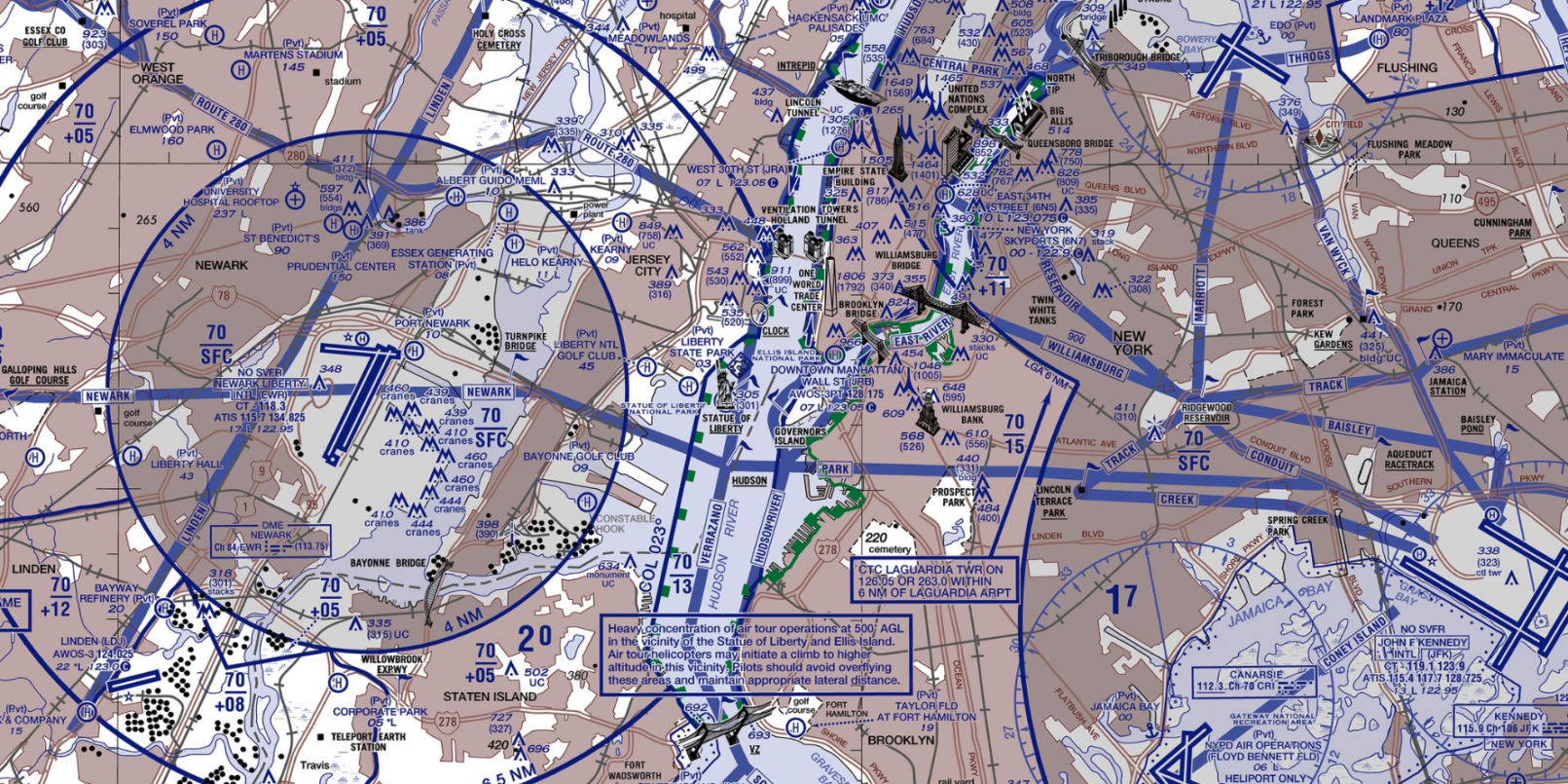

Newly proposed FAA rules could create eVTOL pilot training hurdle

The FAA hasn’t definitively mandated dual controls in eVTOLs used for training, but it seems to be pointing in that direction.

How the war in Ukraine transformed Finnair

On the eve of IATA's AGM in Istanbul, Finnair looks a lot like a microcosm of the industry’s challenges and resilience.

Boeing takes Wisk fully under its wing

Wisk's Gen 6 fully-autonomous eVTOL is now Boeing's clean sheet passenger aircraft design for this decade

Reporting & ANalysis

Business Insight

TAC in Brief

Special Report: Seeking lessons for eVTOL pilot training in the F-35

The eVTOL industry has pointed to the F-35B as a model for how to train pilots in VTOL aircraft that lack dual controls. But what exactly does it take to make this model work?

Hear from us

Join our email list

Subscribe to

The Air Current

Award-winning aerospace journalism that keeps you ahead